Road Project In SIERRA LEONE

A Civil Engineering company based in Republic of Sierra Leone, West Africa which major focus is on

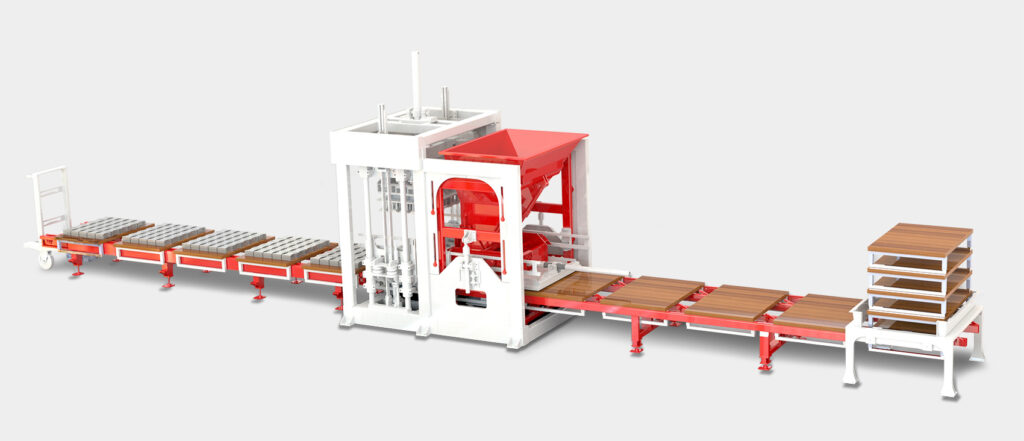

ELKOBLOCK-25 Concrete Block Making Machine has a robust and compact design which provides economical and efficient solution with single concrete hopper.

ELKOBLOCK-25 works with L-type pallets (pallets with feet) and the production takes place fully automatically. Afterwards, the dry products can be stacked on delivery pallets manually or with a fully automatic servo-drive ELKON cubing robot that can be added to the system optionally.

As a result of ELKON’s company standard consisting innovative design and high-technology production, this concrete block making machine, offers modern vibration, hydraulic and automation systems along with heavy duty design.

In this handling configuration, L-type pallets (pallets with feet) are fed into the concrete block machine through the pallet feeding point. After the automatic production process, pallets with wet products on them are manually taken to the curing area via hand-lift or forklift.

It is possible to produce 1000’s of different types of concrete blocks. Please contact us for your requirements.

| Production Board | 1200 x 950 mm |

| Production Area | 1030 x 860 mm |

| Production Height | 60-300 mm |

| Interlocking Paver Production Capacity | 600 m2 in 10 hrs |

| Hollow Block Capacity | 10,000 pcs in 10 hrs |

We can provide optional configurations to meet your specific concrete needs!

A Civil Engineering company based in Republic of Sierra Leone, West Africa which major focus is on

ELKON has recently put into operation another concrete batching plant, which is ELKOMIX-135 Quick Master Compact Concrete

Exclusive Canadian Agent

for Elkon Concrete Batching Plants and Equipment

Okanagan & Fraser Valley, British Columbia, Canada

This packet showcases Elkon’s Block-Making Plants

25, 25 PLUS, S25 and S36