ELKON’s MM-30 is airlifted by Chinook helicopter into the Grand Canyon!

Elkon Canada is proud to spotlight the deployment of the Mix Master-30 Onsite mobile concrete batching plant.

• Power Panel & Electronic Weighing System

• PLC brand: ABB or SIEMENS

• Equipped with cooling fan

• Weight Indicators: Laumas (ITALY)

• Slump values monitored digitally and analog

• Easy & percise calibration

• Convenient maintenance access

• Capacity: 2x5 m³ or 4x5m³

• Vibrators from OLI-WAM (ITALY)

• Saddles adjust flowrate of material

• No concrete ramp needed

• Stores 2-4 types of aggregate

• Dry Filling Capacity: 750L

• Vibrated Concrete Capacity: 500L

• Capacity: 0.5 m³ vibrated concrete/charge

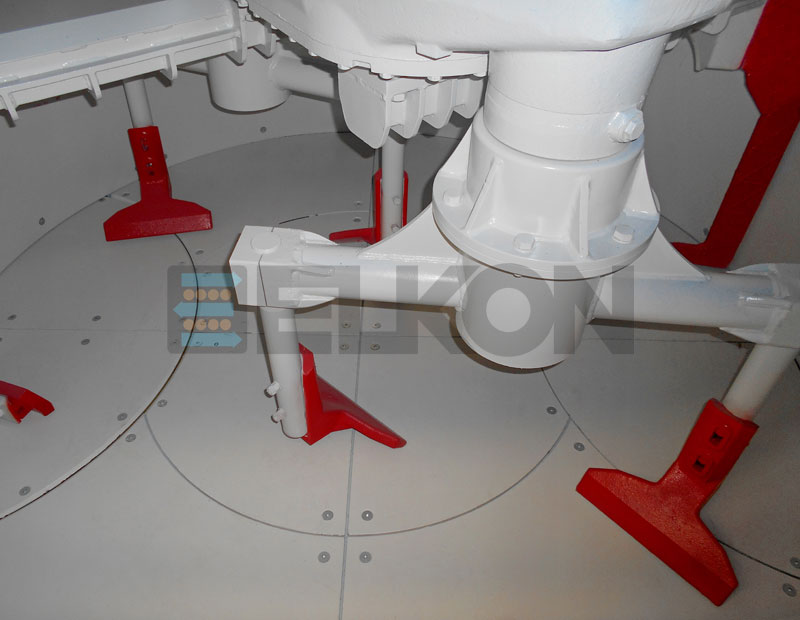

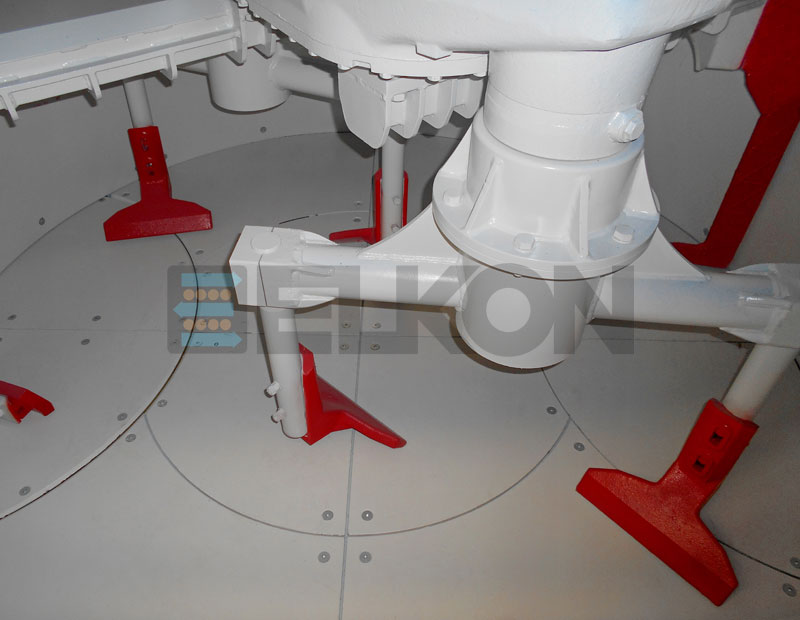

• Aggregates weighed inside mixer

• Mixing Paddle: 5 units (Mn alloyed cast steel )

• Inner Lateral Scraper: 1 unit

• Outer Lateral Scraper: 1 unit

• Drive: 22 kW motor + gearbox

• Cement Feeding Bunker Capacity : 1 m3

• Equipped with grid & covering

• Capacity: 0.5 m³ vibrated concrete/charge

• Cement Screw Capacity: 25 ton/hr

• Dimensions: Ø 165 mm

• Drive system: 4 kW motor+ planetary gearbox

• Equipped with galvanized maintenance lids

• Drive: 22 kW motor + gearbox

• Elkon's centralized lubrication system for supporting bearings

• 200 kg/cm² load transfer capacity

• 10 mm total thickness

• 4/2 coating

• 4 multi layer linen cord

• Chevron belt

• Self-lubricated rollers

• Galvanized main chassis

• Capacity: 20 m³/h

• To feed water into water weigh hopper

The MM-30 produces up to

All components of the on-site concrete Batching Plant, including aggregate storage bins, pan / planetary mixer, cement, water and additive weighing hoppers, water pump, control panel and power board are installed on a single trailer chassis equipped with axle and tires.

Thus, ELKON MIX MASTER-30 On-Site Concrete Batching Plant can be installed on a very small space and can be ready for concrete production within 1 hour. Moreover, there is no need for crane to install ELKON Mix Master-30 On-Site Concrete Batching Plant. Therefore, it allows concrete production in anywhere concrete is required.

Thanks to precise weigh hoppers and automation system which fully controls concrete production process, it is possible to produce concrete according to the international standards.

ELKON MIX MASTER-30 On-Site Concrete Batching Plant can be equipped with either pan or planetary mixer and either 2 or 4 compartments of aggregate with the storage capacity of 5 m³ each as per the customer’s requirements.

ELKON Mix Master-30 On-Site Concrete Batching Plant can be directly accompanied with mobile or stationary concrete pumps. Moreover, it can discharge concrete into truck mixer by means of an optional concrete discharge belt.

Depending on the cement supply conditions, bag and/or big bag cement feeding system or cement silo can be used with ELKON Mix Master-30 On-Site Concrete Batching Plant.

| Capacity | 30 m3/h |

| The Capacity of Aggregate Bins | 2×5 m3 or 4×5 m3 |

| The Capacity of Aggregate Weigh Hopper | Aggregate is weighing in mixer |

| Loading Type of Aggregate to the Mixer | Transfer Conveyor |

| Mixer Capacity | 750/500 l. |

| Mixer Type | Pan / Planetary |

| Cement Weighing Capacity | 300 kg |

| Water Weighing Capacity | 200 kg |

| Additive Weighing Capacity | 1×25 l (for 1 Type Chemical Additive) |

| Control System | Included |

| Operator Cabinet | – |

| Cement Screw Diameter (Ø) | Ø 165 mm |

| Compressor | Included |

| Capacity | 39 yd3/h |

| The Capacity of Aggregate Bins | 2×6.5 yd3 or 4×6.5 yd3 |

| The Capacity of Aggregate Weigh Hopper | Aggregate is weighing in mixer |

| Loading Type of Aggregate to the Mixer | Transfer Conveyor |

| Mixer Capacity | 1/0.7 yd3 |

| Mixer Type | Pan / Planetary |

| Cement Weighing Capacity | 661 lbs |

| Water Weighing Capacity | 441 lbs |

| Additive Weighing Capacity | 1×6.6 gal (for 1 Type Chemical Additive) |

| Control System | Included |

| Operator Cabinet | – |

| Cement Screw Diameter (Ø) | 6 in |

| Compressor | Included |

We can provide optional configurations to meet your specific concrete needs!

Elkon Canada is proud to spotlight the deployment of the Mix Master-30 Onsite mobile concrete batching plant.

Continuously providing effective solutions to its customers, ELKON has been becoming the preferred concrete batching plant supplier

Continuously providing effective solutions to its customers, ELKON has been becoming the preferred concrete batching plant supplier

Exclusive Canadian Agent

for Elkon Concrete Batching Plants and Equipment

Okanagan & Fraser Valley, British Columbia, Canada