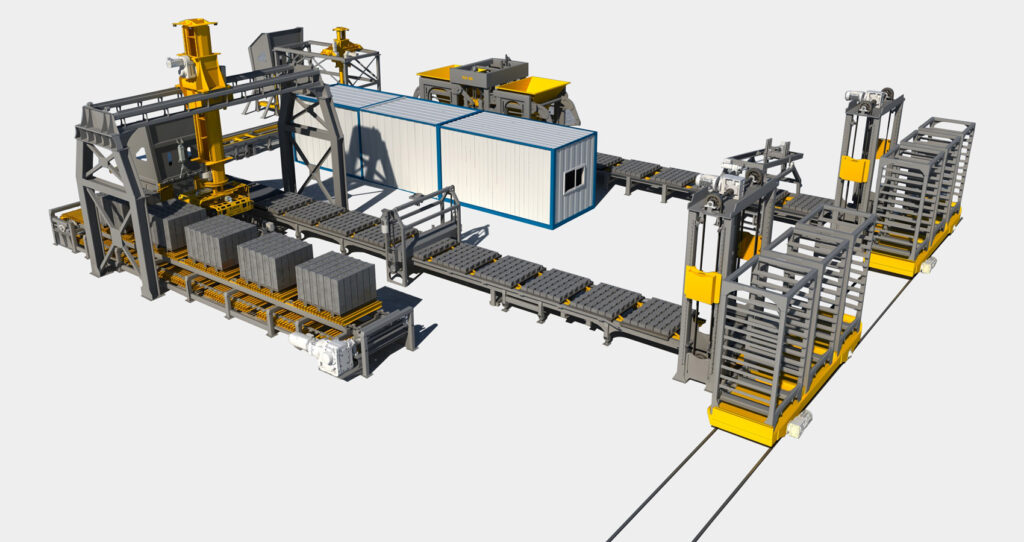

NEW: ELKOBLOCK – S25 Concrete Block Making Machine

The new member of ELKOBLOCK series concrete paver and block machines, ELKOBLOCK-S25 offers optimum production performance with

ELKOBLOCK-S25 offers superior performance and high production capacity. Optimum handling of the production pallets is provided for curing and packaging with steel racks. This way, an optimum performance can be obtained during the production, curing, additional processing and packaging.

Pallets with wet products are placed onto the 10-level steel racks via a special elevator and these racks are taken into the curing area by a forklift. After curing process, steel racks are placed in the pallet lowerator. Fully-automatic servo-drive ELKON cubing robot places the final products onto the delivery pallets and inverted production pallets are fed into the concrete block making machine via conveyor.

Thanks to its highly flexible, user friendly software, ELKOBLOCK-S25 Concrete Block Making Machine provides a high-quality, quick and easy production. Control system, power board and hydraulic system are placed in the operator’s cabin.

Steel racks are being used during the handling process of the production pallets. This way, an optimum performance can be obtained during the production, additional processing, and packaging.

It is possible to produce 1000’s of different types of concrete blocks. Please contact us for your requirements.

| Production Board | 1200 x 950 mm |

| Production Area | 1035 x 860 mm |

| Production Height | 60-300 mm |

| Interlocking Paver Production Capacity | 800 m2 in 10 hrs |

| Hollow Block Capacity 20x40x20cm | 12,000 pcs in 10 hrs |

We can provide optional configurations to meet your specific concrete needs!

The new member of ELKOBLOCK series concrete paver and block machines, ELKOBLOCK-S25 offers optimum production performance with

Exclusive Canadian Agent

for Elkon Concrete Batching Plants and Equipment

Okanagan & Fraser Valley, British Columbia, Canada

This packet showcases Elkon’s Block-Making Plants

25, 25 PLUS, S25 and S36